Unlocking Efficiency With Signage in Manufacturing

WRITTEN BY: TelemetryTV, 04-02-2025

Signage in manufacturing is entering a new era of real-time communication. On the factory floor, a wall-mounted screen might flash red if a machine needs maintenance, while in the front office, another display cycles through live production dashboards. When used effectively, these visual tools ensure every team member—from frontline operators to top executives—receives critical information instantly.

Many manufacturers now adopt cloud-based digital signage software for this purpose. TelemetryTV’s digital signage software solutions centralize screen management across one or multiple locations. This lets teams control safety alerts, performance dashboards, and announcements from a single source, ensuring up-to-date messaging for every work cell or department.

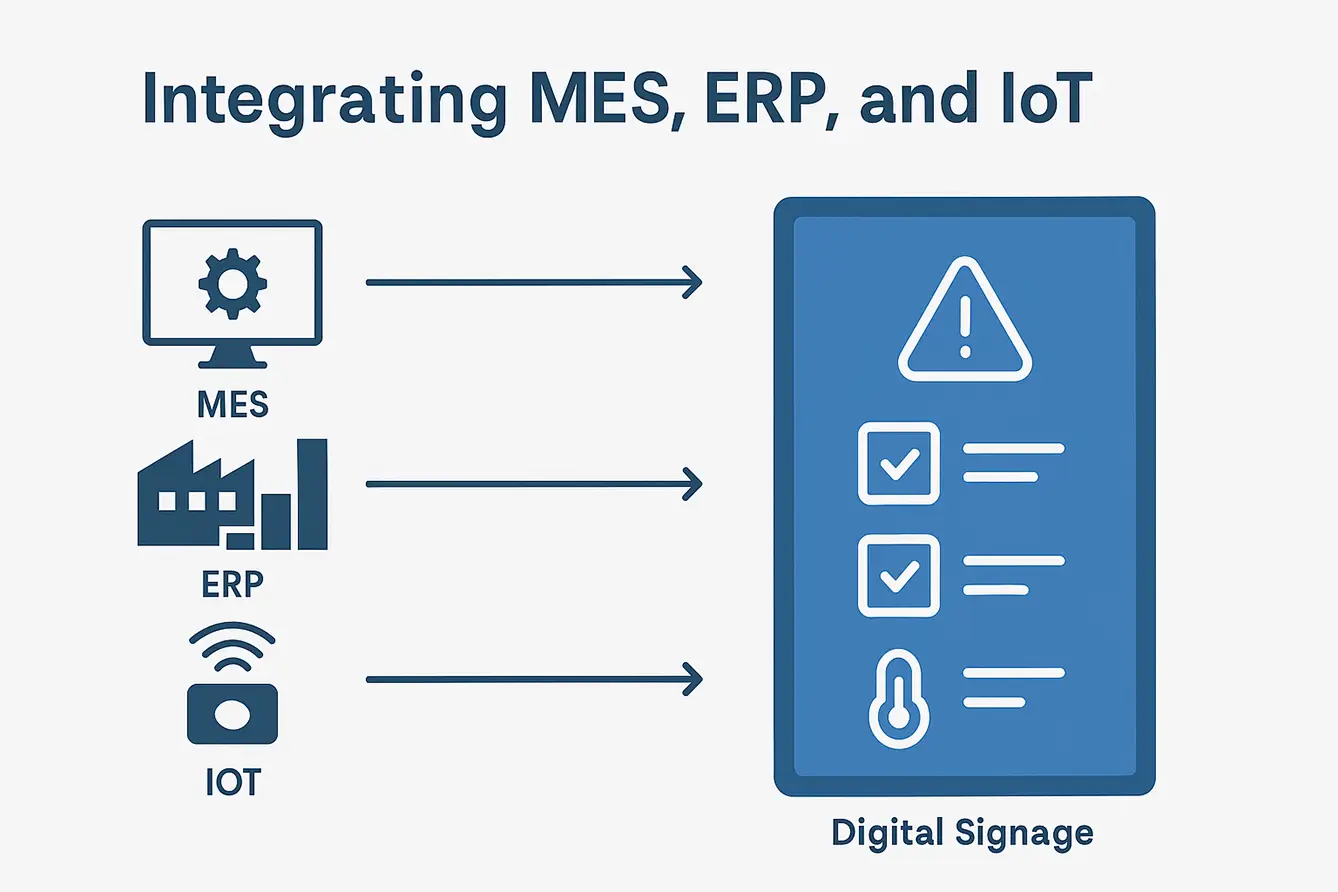

Below, we explore how signage in manufacturing unites the factory floor and front office, improves safety, streamlines lean production, and engages employees. By integrating with MES, ERP, and IoT data streams, it becomes the final mile in delivering actionable information to the people who need it most.

Bridging Shop Floor Silos

Traditionally, production and executive teams functioned in separate spheres. Operators on the shop floor rarely saw corporate announcements, and office staff had limited visibility into on-floor metrics. Digital signage in manufacturing eliminates these silos by displaying operational data and organizational updates in shared spaces.

Large screens in assembly areas can show current output or shift goals, while displays in corporate offices highlight financial KPIs or major project milestones. Because everything is managed in one cloud-based interface, updates propagate immediately. This unified channel ensures everyone, whether in production or administration, aligns on daily objectives and overarching goals.

Safety Compliance in Focus

Safety ranks among the most vital priorities in a plant environment. Digital signage software solutions heighten awareness by delivering clear, timely safety messaging. If a spill occurs, screens across the facility can override normal content to display evacuation instructions or hazard alerts. Under normal conditions, displays remind employees about personal protective equipment, lockout/tagout guidelines, and safe handling procedures.

Studies suggest that replacing static posters with dynamic digital signage reduces incident rates by about 20%. Real-time IoT triggers further enhance safety. For example, if a sensor flags high heat, a nearby screen can show a warning, encouraging immediate preventive action. In loud environments, these visual alerts cut through ambient noise and help ensure compliance.

Lean Manufacturing: Real-Time Visibility

Lean manufacturing hinges on immediate, data-driven feedback loops. Signage in manufacturing broadcasts core metrics—like cycle times, takt times, or OEE—to everyone on the floor. Operators see if they are hitting hourly targets or running behind, prompting quicker adjustments to maintain throughput. Plants adopting real-time KPI dashboards often report defect reductions of up to 41%.

When production issues arise, cloud-based digital signage software can act as an automated andon board. It notifies supervisors or maintenance teams the moment performance deviates from standard. Quicker responses reduce wasted materials and idle labor. In turn, fewer slowdowns benefit the entire workflow, from raw material intake to final output.

Case: Kenco's 40% Engagement Jump

3PL firm Kenco Logistics observed that digital signage boosted both efficiency and employee involvement. After installing screens to show real-time metrics and upcoming improvement events, participation in optional programs rose by 40%. Similar trends appear across manufacturing, where integrated signage fosters a culture of continuous improvement and direct engagement with frontline teams.

Integrating MES, ERP, and IoT

Manufacturers rely on data from multiple platforms: MES for production, ERP for inventory and orders, and IoT for machine conditions. Software for digital signage serves as a bridge, drawing relevant information from each system and presenting it in actionable dashboards. If the MES detects out-of-spec production, an alert appears on screens, prompting immediate intervention. ERP-driven displays keep shipping and production teams aligned on upcoming orders or material levels.

IoT sensor data elevates predictive maintenance. If vibrations or temperature exceed preset thresholds, signage in manufacturing can alert operators before breakdowns occur. This proactive approach curtails downtime, reduces scrap, and supports lean initiatives by catching minor issues before they become major disruptions.

Employee Engagement and Internal Comms

A productive plant depends on motivated employees. Yet many frontline workers lack daily email access, relying on word of mouth or bulletin boards for updates. Digital signage software solutions bridge that gap by broadcasting daily briefings, success stories, training clips, and event notices. Breakroom screens might feature service milestones or nutritional tips alongside shift changes.

Surveys reveal internal communication effectiveness can climb over 50% after a plant installs networked displays. Employees become more invested in corporate happenings, feel recognized, and better understand how their work aligns with organizational targets.

Technical Integration Table

| System | Key Data | Signage Application |

|---|---|---|

| MES | Production rates, OEE | Real-time dashboards, downtime alerts |

| ERP | Inventory, orders | Scheduling boards, shipment statuses |

| IoT | Machine conditions | Predictive maintenance alerts |

Centralized Cloud Management

A major factor driving adoption is the ease of cloud-based digital signage software. Administrators can track device statuses, schedule updates, and push content to screens from any location. Even if network connectivity falters, devices cache content so important messages remain visible.

This architecture enables quick scaling from a pilot of a few displays to an enterprise-wide deployment. Role-based permissions let HR, operations, or safety teams each manage relevant screens without overwriting each other’s content. Consistent branding and compliance directives can be enforced system-wide with minimal manual effort.

Transforming the Modern Plant

As manufacturers pursue Industry 4.0 initiatives, signage in manufacturing becomes an indispensable interface, transforming raw data into actionable insights. Live dashboards reduce defects, integrated alerts prevent downtime, and safety reminders protect employees. In parallel, an engaged workforce feels closer to corporate strategy, building a stronger culture.

Leading companies such as Hitachi, JBS Foods, POLYWOOD, Cameco, Redwood Plastics and Rubber, and Eberswalder implement TelemetryTV’s digital signage software solutions for exactly these reasons. From the factory floor to the front office, real-time communication drives agility and competitiveness, proving that well-executed signage delivers a measurable return on investment.

Ready to Experience It Yourself?

If you want to unify data silos, reduce downtime, and boost engagement in your manufacturing environment, it may be time to explore software for digital signage. Automated production dashboards, emergency alerts, and global updates all become effortless with a reliable, cloud-managed solution. The result is a safer, more efficient plant that keeps pace with modern demands.

Accelerate Digital Communication

Take the next step toward a safer, more efficient manufacturing environment using TelemetryTV's digital signage software. Experience real-time messaging that boosts productivity.

Start for Free